Ultrasound Versus IR: Making decisions about real-time location systems

July 09, 2018

By Trevor Bromley, contributing reporter

For healthcare systems, the maxim “time is money” holds more truth today than ever before. The need to increase efficiency, decrease patient wait-time, increase satisfaction – all of it needs to happen to keep hospitals healthy. One of the most direct ways to increase efficiency is to know where equipment and people are when you need them, and that’s where real-time location systems (RTLS) are worth their weight in gold.

RTLS is the type of technology where one size doesn’t fit all, so it’s a good idea to do your homework when choosing a system. It’s also essential to understand the different technologies available. While there are a number of technologies like Bluetooth low energy (BLE) and radio frequency (RF) sometimes used in hospitals for basic asset tracking, two supplemental technologies (infrared and ultrasound) can greatly improve accuracy of the location systems.

Before delving into the attributes of infrared (IR) and ultrasound, it’s important to understand how RTLS delivers value and what can derail it from providing value. Consider an example that nearly anyone can relate to – missing keys. If you’ve ever misplaced your car or house keys, you stopped and thought about where you left them, or you searched room to room until you found them. In a hospital, whether it’s equipment or a caregiver, even if you know where you saw them, that doesn’t mean they will still be there even seconds later. Searching each room can take precious minutes or even hours, and during the course of the search, the caregiver or equipment could always move into a location previously searched. Using RTLS, employees can quickly pinpoint the equipment and caregiver they’re looking for within a few feet or even within inches, depending on the technology.

Infrared RTLS (IR) uses light-based energy. This provides a few advantages over ultrasound, but the advantages are not significant enough for most users in a healthcare setting to appreciate. Case in point, light travels faster than sound, so the communications back to the transmitter would be faster, but the split-second delay won’t be noticeable.

On the other hand, the drawbacks do have the ability to cause some unpleasant hiccups. IR can pass through glass for example, necessitating the use of extra devices to “block” the signal or masking materials like blinds to reduce the instances of “other side of the wall” events. In hospitals with open line-of-sight designs using lots of glass and transparent materials, IR pass-through can lead to staff getting to where the RTLS says the equipment or caregiver is, seeing that they’re actually on the other side of a glass window or wall causing significant inefficiencies. This issue is exacerbated by the fact that IR doesn’t typically get closer than a foot or two with its location pinpoints, and that distance is enough to be the difference between being in one room or another room on the other side of a window.

Beyond IR’s ability to travel through glass, its accuracy can be impacted by still ubiquitous fluorescent lighting. Certain surfaces and materials may also cause issues. If a material reflects light it can, and often does, reflect IR. So glass partitions and windows can again cause problems, but so can in-room monitors and even some floor surfaces. The need to control light signals in order to overcome those obstacles requires many transmission devices to achieve the desired level of accuracy.

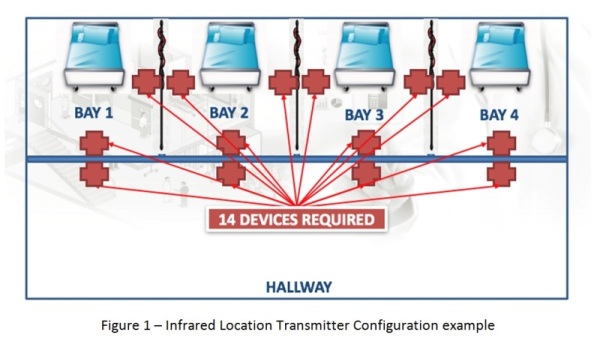

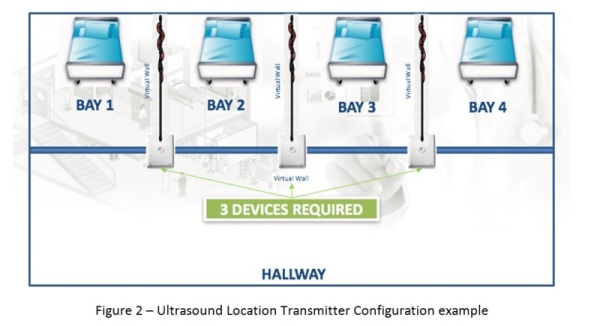

Ultrasound, as a sound-based technology, doesn’t pass through glass (think of recording studio sound booths where the engineer can see the musician, but has to communicate via a PA). So if an ultrasound-based system is giving you the location of the equipment or caregiver you’re looking for within a room, they will actually be in that room – especially since ultrasound’s locating accuracy can be measured in inches. This means that an open-plan hospital design can continue to look as it was first envisioned without having to make accommodations in order to use the RTLS. Ultrasound transmission devices can also create up to four distinct zones per unit, whereas IR-based transmitters can only handle one zone per unit (see figures 1 and 2), requiring a higher number of devices if bay-level accuracy is required.

Depending on your take, the power source for IR or ultrasound will either be a positive or a negative. The lithium batteries used for IR are expensive and they’re rough on the environment, requiring expensive disposal procedures.

By contrast, ultrasound systems can use standard 1.5V D cell batteries, which are more affordable, easier to track down and easier to recycle. Both D cell and lithium batteries do have rechargeable options, but you should confirm with the manufacturer that it’s alright to use rechargeable before you go that route.

Lithium battery-powered IR RTLS also require more units. Due to the number of transmission devices required, an ambulatory recovery room with four bays separated by curtains would require 14 location devices to deliver bay-level accuracy to create zones in order to control light and ensure line-of-sight confirmation. By contrast, ultrasound systems in the same room would require just three units.

Ultrasound also requires little to no maintenance after it is set up, almost being a “set it and forget it” system. The majority of employee time will be spent on routine tag and transmitter maintenance (assigning tags/badges and replacing batteries). IR, with the higher number of units needed to provide bay-level accuracy, requires a more intensive install, and needs continual monitoring and tuning to optimize performance, due to the challenge of managing the properties of light. A comparison between two multi-facility healthcare systems, each with 500+ beds, showed the system with the IR-based RTLS required the commitment of 10 full-time employees, while the ultrasound-based system required only two full-time employees.

With RTLS being an investment and a big benefit, the research you do upfront will be well worth it. When doing your research, ask questions of the manufacturers, ask other peers at other facilities about their experience, and consider your present needs as well as your needs for the future. Time is money, but that will be time well spent.

For healthcare systems, the maxim “time is money” holds more truth today than ever before. The need to increase efficiency, decrease patient wait-time, increase satisfaction – all of it needs to happen to keep hospitals healthy. One of the most direct ways to increase efficiency is to know where equipment and people are when you need them, and that’s where real-time location systems (RTLS) are worth their weight in gold.

RTLS is the type of technology where one size doesn’t fit all, so it’s a good idea to do your homework when choosing a system. It’s also essential to understand the different technologies available. While there are a number of technologies like Bluetooth low energy (BLE) and radio frequency (RF) sometimes used in hospitals for basic asset tracking, two supplemental technologies (infrared and ultrasound) can greatly improve accuracy of the location systems.

Before delving into the attributes of infrared (IR) and ultrasound, it’s important to understand how RTLS delivers value and what can derail it from providing value. Consider an example that nearly anyone can relate to – missing keys. If you’ve ever misplaced your car or house keys, you stopped and thought about where you left them, or you searched room to room until you found them. In a hospital, whether it’s equipment or a caregiver, even if you know where you saw them, that doesn’t mean they will still be there even seconds later. Searching each room can take precious minutes or even hours, and during the course of the search, the caregiver or equipment could always move into a location previously searched. Using RTLS, employees can quickly pinpoint the equipment and caregiver they’re looking for within a few feet or even within inches, depending on the technology.

Infrared RTLS (IR) uses light-based energy. This provides a few advantages over ultrasound, but the advantages are not significant enough for most users in a healthcare setting to appreciate. Case in point, light travels faster than sound, so the communications back to the transmitter would be faster, but the split-second delay won’t be noticeable.

On the other hand, the drawbacks do have the ability to cause some unpleasant hiccups. IR can pass through glass for example, necessitating the use of extra devices to “block” the signal or masking materials like blinds to reduce the instances of “other side of the wall” events. In hospitals with open line-of-sight designs using lots of glass and transparent materials, IR pass-through can lead to staff getting to where the RTLS says the equipment or caregiver is, seeing that they’re actually on the other side of a glass window or wall causing significant inefficiencies. This issue is exacerbated by the fact that IR doesn’t typically get closer than a foot or two with its location pinpoints, and that distance is enough to be the difference between being in one room or another room on the other side of a window.

Beyond IR’s ability to travel through glass, its accuracy can be impacted by still ubiquitous fluorescent lighting. Certain surfaces and materials may also cause issues. If a material reflects light it can, and often does, reflect IR. So glass partitions and windows can again cause problems, but so can in-room monitors and even some floor surfaces. The need to control light signals in order to overcome those obstacles requires many transmission devices to achieve the desired level of accuracy.

Ultrasound, as a sound-based technology, doesn’t pass through glass (think of recording studio sound booths where the engineer can see the musician, but has to communicate via a PA). So if an ultrasound-based system is giving you the location of the equipment or caregiver you’re looking for within a room, they will actually be in that room – especially since ultrasound’s locating accuracy can be measured in inches. This means that an open-plan hospital design can continue to look as it was first envisioned without having to make accommodations in order to use the RTLS. Ultrasound transmission devices can also create up to four distinct zones per unit, whereas IR-based transmitters can only handle one zone per unit (see figures 1 and 2), requiring a higher number of devices if bay-level accuracy is required.

Depending on your take, the power source for IR or ultrasound will either be a positive or a negative. The lithium batteries used for IR are expensive and they’re rough on the environment, requiring expensive disposal procedures.

By contrast, ultrasound systems can use standard 1.5V D cell batteries, which are more affordable, easier to track down and easier to recycle. Both D cell and lithium batteries do have rechargeable options, but you should confirm with the manufacturer that it’s alright to use rechargeable before you go that route.

Lithium battery-powered IR RTLS also require more units. Due to the number of transmission devices required, an ambulatory recovery room with four bays separated by curtains would require 14 location devices to deliver bay-level accuracy to create zones in order to control light and ensure line-of-sight confirmation. By contrast, ultrasound systems in the same room would require just three units.

Ultrasound also requires little to no maintenance after it is set up, almost being a “set it and forget it” system. The majority of employee time will be spent on routine tag and transmitter maintenance (assigning tags/badges and replacing batteries). IR, with the higher number of units needed to provide bay-level accuracy, requires a more intensive install, and needs continual monitoring and tuning to optimize performance, due to the challenge of managing the properties of light. A comparison between two multi-facility healthcare systems, each with 500+ beds, showed the system with the IR-based RTLS required the commitment of 10 full-time employees, while the ultrasound-based system required only two full-time employees.

With RTLS being an investment and a big benefit, the research you do upfront will be well worth it. When doing your research, ask questions of the manufacturers, ask other peers at other facilities about their experience, and consider your present needs as well as your needs for the future. Time is money, but that will be time well spent.