by

Lauren Dubinsky, Senior Reporter | May 08, 2018

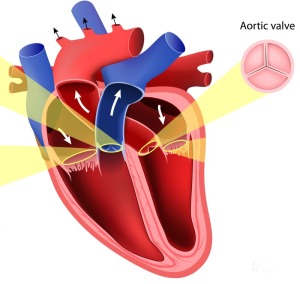

A new 3D printing technology may reduce risks of complications from heart valve replacement, according to a study presented at the Society for Cardiovascular Angiography and Interventions Scientific Sessions late last week in San Diego.

“Our models allow us to use the pre-procedure CT data to create a 3D printed model that can then be implanted with a valve and this can then be analyzed for areas of potential paravalvular leak (PVL),” Dr. Sergey Gurevich, lead author of the study and Cardiovascular Fellow at the University of Minnesota, told HCB News.

Transcatheter aortic valve replacement (TAVR) is performed on intermediate, high-risk and inoperable patients to replace a damaged valve with a prosthetic valve. According to Gurevich, PVL occurs in up to 12 percent of patients.

Ad Statistics

Times Displayed: 2009

Times Visited: 8 Fast-moving cardiac structures have a big impact on imaging. Fujifilm’s SCENARIA View premium performance CT brings solutions to address motion in Coronary CTA while delivering unique dose saving and workflow increasing benefits.

The study included six patients undergoing TAVR for severe, calcific aortic stenosis who were at risk of PVL. They underwent CT scans and those images were analyzed and segmented to aid in printing the 3D models.

The CT images provided a 360-degree view of the location of the calcium build up, and the 3D models enabled the researchers to further assess potentially ill-fitting valves. The 3D models were then implanted with the valve to determine if the size was correct.

“In order to identify the leak pre-procedure, a valve needs to be implanted,” said Gurevich. “The CT scans are done prior to the implantation of the valve, and so they are unable to show PVL since the valve was not yet been implanted.”

The research team then evaluated the 3D models for final analysis and compared them to

in vivo implanted TAVR echocardiograms. They found that every leak seen with the 3D model was confirmed on the CT scans.

The next step is to determine the exact size of the leak. The team is working with computational fluid dynamics to optimize calculations, and plans to conduct a functional study.