by

Thomas Dworetzky, Contributing Reporter | April 20, 2017

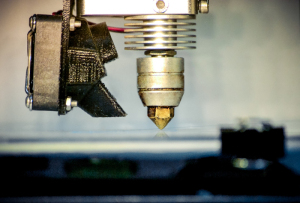

Printing 3-D models of organs from scanning data is just another way in which this revolutionary technology is pushing the boundaries of medical technology – and the models are proving a boon to patients and physicians alike.

For people like Erica Endicott, whose son Kaden had a malformed heart repaired by doctors at Phoenix Children’s Heart Center, “it was incredible to get an actual, tangible model of our son’s heart,” she

told GE Reports. “It helped us better understand the defect.”

The Phoenix team made their before-and-after-procedure models of Kaden's heart from an ultrasound system.

Ad Statistics

Times Displayed: 68650

Times Visited: 2236 Ampronix, a Top Master Distributor for Sony Medical, provides Sales, Service & Exchanges for Sony Surgical Displays, Printers, & More. Rely on Us for Expert Support Tailored to Your Needs. Email info@ampronix.com or Call 949-273-8000 for Premier Pricing.

The technology today is still time-consuming and labor-intensive, but it may not be forever.

“Today, when people print organs, it can take anywhere from a week to three weeks to manipulate the data,” noted Jimmie Beacham, Waukesha, Wisconsin-based chief engineer for advanced manufacturing at GE Healthcare. “We want to do it with a click of a button.”

To that end, GE researchers are now tackling the problem of developing software that can turn the enormous data files from machines like CT scanners into a printable file that can quickly produce a physical model with a 3-D printer. “We’ve already printed several organs like the liver and the lung,” he said, “It’s valuable learning.”

The competition in the space is out there, he noted, and his team is working with the business unit GE Additive to explore whether “a custom machine that prints organs from the files that we derive from our software” makes sense,” adding that “if we don’t figure it out, someone else will.”

The models are good for more than just patient education, as Beacham observed. “Surgeons sometimes have to repeatedly go to a workstation, look at the image on the screen and try to figure out what’s going on,” as anatomy varies between patients and can lead to rude surprises during an operation. “It slows the surgery down and increases the odds of introducing infection or slowing the patient’s recovery time.”

Exact anatomic replicas can help surgeons-to-be sharpen their skills as well.

At the University of Michigan, for example,

researchers are using 3-D printed lifelike replicas to provide a cost-efficient tool to improve practical experience for more surgical trainees, they reported in an article published in

Otolaryngology – Head and Neck Surgery in April.

"3-D printing is bringing a whole new meaning to hands-on experience for surgeons-in-training," said Dr. David Zopf, the article's senior author and a pediatric head and neck surgeon at C.S Mott Children's Hospital.