by

Sean Ruck, Contributing Editor | December 01, 2014

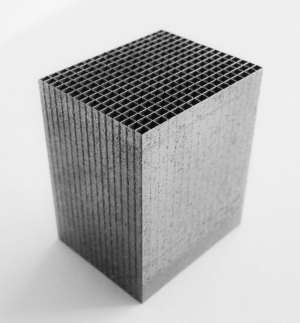

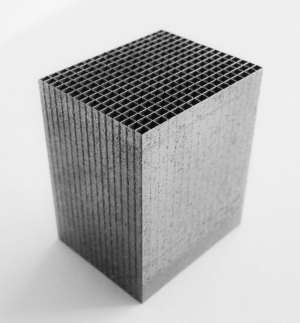

3-D printed pure Tungsten grid

At RSNA on Sunday, Smit Röntgen upped the ante on 3-D printing. The company, a part of the Philips Healthcare brand, showcased a variety of 3-D printed pure tungsten products at Dunlee's booth (Dunlee is a division of Philips).

Utilizing technology developed with EOS GmbH, the pure tungsten parts are created by using a laser to melt together successive layers of pure tungsten powder. Each layer is precisely placed and then the laser super-heats the material in a process called powder bed laser fusion.

The process enables Smit Röntgen to create tungsten products with incredibly precise measurements. For example, the company can produce collimators with wall thicknesses of less than 100 micrometers, with the thin walls helping to minimize X-ray scatter.

Ad Statistics

Times Displayed: 126612

Times Visited: 7270 MIT labs, experts in Multi-Vendor component level repair of: MRI Coils, RF amplifiers, Gradient Amplifiers Contrast Media Injectors. System repairs, sub-assembly repairs, component level repairs, refurbish/calibrate. info@mitlabsusa.com/+1 (305) 470-8013

The project began seven years ago, according to Harry Kleijnen, manager of development and engineering, collimation solutions for Philips Healthcare and the designer behind the process.

Other 3-D printed pure tungsten products are also being introduced with further applications including thermal and shielding for use in X-ray tubes, for example. Kleijnen says customers will benefit from the ability to highly customize parts without having to create expensive molds, helping to keep costs down.

Currently, about 30 parts can be created in a day, but planning is already underway to open a plant that will be able to produce about 40,000 pieces per year.