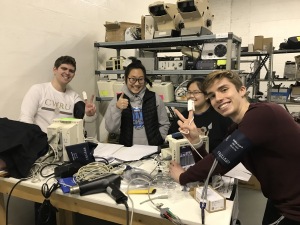

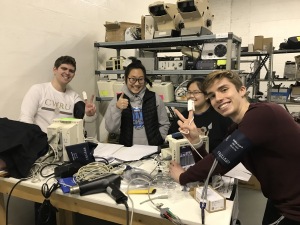

Julian Narvaez and classmates at Case Western Reserve University reverse engineer pulse oximeters. Courtesy, Julian Narvaez

From the August 2021 issue of HealthCare Business News magazine

By Julian Narvaez

The problem-solving aspect of engineering appealed to me since I was young. I would tinker with Legos in attempts to create useful inventions to be used around the house. Legos and strings were combined to create an, albeit faulty, coffee pouring machine. This fascination with utility continued as I grew older. Medical devices appealed to me as useful devices; what greater utility could be found in a device than that of a pacemaker to a cardiac patient?

I took this inclination toward medical devices to Case Western Reserve University (CWRU) and graduated with a degree in Electrical Engineering this past May. During my time completing my bachelors I was exposed to sustainability ideas such as device end-of-life, circularity; and became interested in medical device reprocessing. During my time at CWRU, I witnessed the benefits of reprocessing medical equipment while working on an NIH grant dedicated to studying medical device end-of-life.

Designing for sustainability

Part of my work with the NIH R25 grant involved investigating potential fixes for common device failure modes. A few fixes, such as replacing blood pressure cuff tubing and AC power cables, were relatively inexpensive and could be done without much hassle.

However, more often than not, costs would ramp up quickly when it came to replacing pulse oximeter cables, single-use AED batteries, and wheelchair controllers. Most device fixes would require proprietary replacement parts that would need to be sourced directly from the original equipment manufacturer (OEM). Device manuals were hard to come by as well. These issues became readily apparent when attempting to replace a powered wheelchair’s dead batteries.

Wheelchair leg holders blocked the battery compartment when first attempting to access the dead batteries. Numerous attempts to remove the leg holder were futile, no amount of unscrewing, pulling, and hammering were enough to budge the leg holders. The singular method of lifting the leg holders without damaging the wheelchair is to provide electric power to the wheelchair to lift the seat. This presented the dilemma; how can the batteries be replaced when the only way to access the batteries is with working batteries? The solution to the Catch-22 was a proprietary cable the OEM designed to deliver power externally to the wheelchair.

To be clear, the majority of power wheelchairs are easier to maintain, this example instead highlights the challenges technicians and reprocessors face when repairability and circularity are not prioritized during the design process. A wheelchair is a durable, reusable medical device, but many devices are specifically labelled for “single-use.” Some of these are noninvasive, such as pulse oximeters and blood pressure cuffs, while others are more invasive such as surgical and diagnostic medical devices. For single-use devices, or SUDs, the subsequent life of the product is simply ignored. This is wasteful: economically and environmentally.